Unlocking Sturdiness: The Value of Top Quality Undercarriage Parts in Building And Construction

Unlocking Sturdiness: The Value of Top Quality Undercarriage Parts in Building And Construction

Blog Article

Vital Guide to Undercarriage Components for Heavy Tools

When it comes to hefty equipment, the undercarriage plays a crucial role in making sure effective and smooth procedures. From track chains to rollers and idlers, each element adds to the overall functionality of the devices.

Importance of Undercarriage Parts

Understanding the essential role that undercarriage parts play in the performance and long life of hefty tools is extremely important for reliable upkeep and operation - undercarriage parts. The undercarriage components form the structure on which the entire machine operates, supporting the weight of the equipment, providing security, and absorbing shock loads during operation. A well-maintained undercarriage not only ensures smooth operation yet also contributes considerably to minimizing downtime and repair service expenses

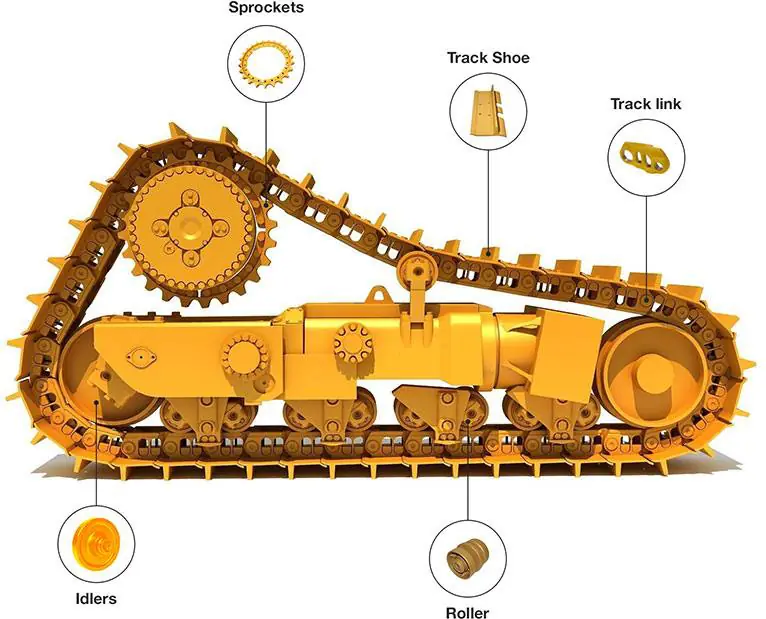

The undercarriage is composed of various essential components such as track chains, track shoes, sprockets, idlers, rollers, and track structures. The track chains and track shoes aid in giving traction and assistance, while the sprockets and idlers aid in driving the tracks smoothly.

Kinds of Track Chains

Track chains are necessary components of heavy tools undercarriages, providing the needed traction and assistance for reliable operation. There are mostly two kinds of track chains used in heavy tools: secured and lubricated track chains (SALT) and dry track chains. Secured and lubricated track chains are frequently found in contemporary hefty equipment. These chains are pre-lubricated and sealed to avoid dirt, debris, and wetness from getting in the chain joints, ensuring smooth procedure and expanding the chain's lifespan. On the other hand, completely dry track chains call for normal manual lubrication to keep optimum performance and prevent premature wear.

Function of Rollers and Idlers

Rollers and idlers play a vital duty in sustaining and leading the track chains of hefty devices undercarriages, adding to the general security and efficiency of the machinery. Idlers, on the various other hand, guide the track chain and aid keep correct stress throughout the undercarriage system.

Together, idlers and rollers work in harmony to make sure that the track chain stays in place, even on rough terrain, enhancing the devices's efficiency and longevity. Appropriate upkeep and normal assessment of idlers and rollers are important to prevent premature wear and potential break downs, eventually maximizing the efficiency and life expectancy of heavy devices undercarriages.

Recognizing Gears

One critical element of sprockets is making certain appropriate positioning and tension to avoid early wear and damages. Misaligned sprockets can create unequal endure the track chain, resulting in decreased effectiveness and possible security hazards. Normal maintenance and inspection of sprockets are essential to determine any indications of wear or misalignment promptly.

Furthermore, gears are available in click over here now numerous sizes and tooth setups, depending on the certain heavy devices and its desired usage. Proper choice of gears based on the devices's requirements is important to make sure optimum performance and durability of the undercarriage system. Understanding the function of gears and their upkeep needs is important for taking full advantage of the performance and life expectancy of hefty tools undercarriages.

Upkeep Tips for Longevity

To guarantee the long term toughness and optimal performance of hefty devices undercarriages, attentive maintenance techniques are vital. Routinely evaluating undercarriage parts such as track shoes, rollers, idlers, and gears for wear and tear is essential. Correct track tension change is also crucial for lowering premature wear on undercarriage parts.

Conclusion

In conclusion, undercarriage components are important components for heavy equipment, playing essential roles in keeping security and performance. Appropriate care and attention to undercarriage components are vital to maximizing tools life-span and performance.

The undercarriage is composed of numerous important components such as track chains, track footwear, gears, idlers, rollers, and track frameworks. pop over to these guys The track chains and track shoes aid in giving traction and support, while the gears and idlers help in driving the tracks smoothly (undercarriage parts). There are largely 2 types of track chains made use of in hefty devices: secured and oiled track chains (SALT) and dry track chains. Proper option and maintenance of track chains are crucial to make certain the general performance and long life of heavy tools undercarriages

Gears are important parts of heavy devices undercarriages, liable for moving power from the machinery to the track chain.

Report this page